Products

Stirred reactor energy optimizer: Our patent pending technology ensures reduction of electrical energy consumption in stirred vessel without compromising process objectives. A promising technology with potential to reduce electrical energy consumption by upto 20-40%. A unique microprocessor controlled interactive system is designed with inbuilt recipe control and safety interlocks.

Automatic catalytic reaction system: Our patent pending fully automated catalytic reaction system helps you to reduce catalyst screening time and fast track commercialization.At the commercial scale this system is useful for screening the catalysts suitable for a chemical process and for obtaining optimum operating parameters. At the laboratory scale, it is useful in the development of new catalyst and studying the catalyst activity and selectivity for the desired product. Our proprietary catalytic reaction system is useful in the evaluation of catalysts, feedstocks and process parameters. Catalytic reaction system is designed with inbuilt recipe control, safety interlocks and handles reaction temperature upto 800°C and pressure 120bar.

Automatic catalytic reaction system: Our patent pending fully automated catalytic reaction system helps you to reduce catalyst screening time and fast track commercialization.At the commercial scale this system is useful for screening the catalysts suitable for a chemical process and for obtaining optimum operating parameters. At the laboratory scale, it is useful in the development of new catalyst and studying the catalyst activity and selectivity for the desired product. Our proprietary catalytic reaction system is useful in the evaluation of catalysts, feedstocks and process parameters. Catalytic reaction system is designed with inbuilt recipe control, safety interlocks and handles reaction temperature upto 800°C and pressure 120bar.

ViscoMix: Innovative ViscoMix agitator for mixing liquids of significantly different properties. Potential application are pharmaceutical emulsions, oil/wax, adhesive coloration, paint blending, fibre lumps, bioreactor. Dispersive and distributive mixing achieve homogenity. Custom made design to suit customer application.

Automatic stirred vessel system: Our patent pending fully automated stirred vessel reaction system helps you to improve the productivity of research and fast track commercialization. It is easy to setup and operate without intervention of operator. A microprocessor controlled stirred vessel reaction system is designed with inbuilt recipe control and safety interlocks.

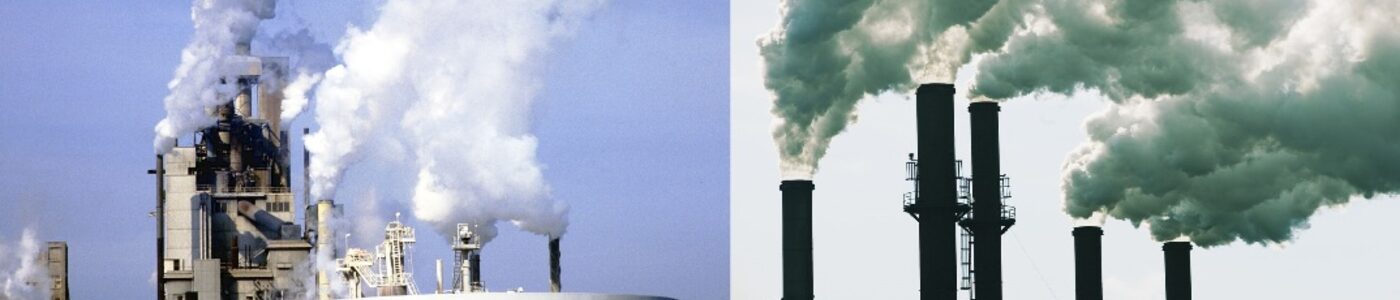

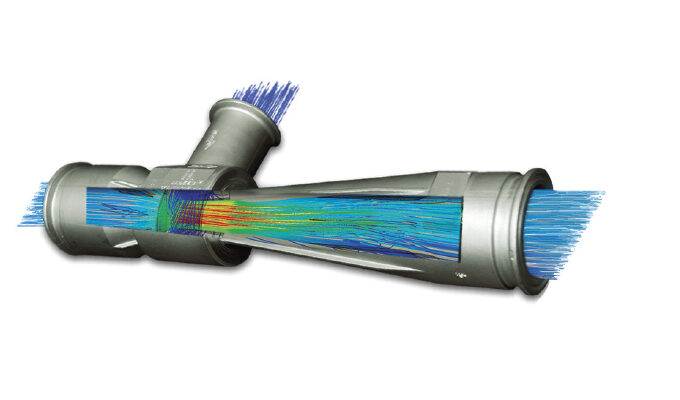

Venturi Scrubbers and Ejectors: Bernoulli's principle of fluid flow system is of vast advantage for industry. Venturi Scrubber system applications are to breath fresh air. Industrial polluting gases like NOx, SOx, acidic vapors are absorbed in circulating reactive liquids. It offers compact system with little maintenance. Our team is expert in understanding customer needs and delivering customized solutions. We perform fluid dynamic studies to to enhance reliability.

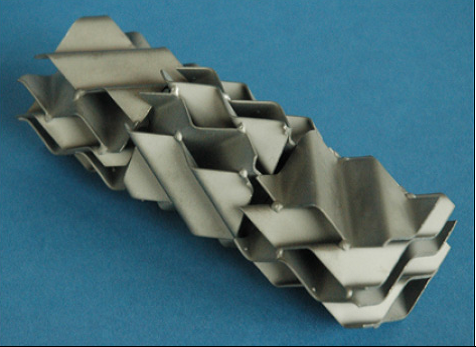

Static Mixers: Static Mixers are used in industry to carry out mixing operation such as mixing of miscible fluids, heat transfer and thermal homogenization, or liquid–liquid dispersion, as well as gas–liquid dispersion. Static mixers offer advantages such as no moving parts, small space requirements, little or no maintenance requirements, many construction materials, narrow residence time distributions, enhanced heat transfer, and low power requirements.

In fact, the only energy cost, represented by motionless mixers, comes from the external pumping power needed to propel materials through the mixer. That is why their use for continuous processes is an attractive alternative to classical agitation devices, since similar

and sometimes better performances can be achieved at a lower cost.

Design of static mixer has two important parameters - mixing efficiency and NTU for desired separation.

With respect to the important role of the geometrical parameters of a static mixer, we use Computational Fluid Dynamics modeling as a powerful tool for evaluating the influence of geometrical parameters (such as length, diameter and pressure drop that are caused by special arrangement of static mixer planes) on mixing efficiency and the pressure drop of a commercial scale static mixer.

We perform theoretical calculation of Number of transfer units NTU required to achieve desired mass transfer. Liquid-liquid equilibrium data is referred through international journals or generated in-house. Height equivalent to theoretical plates HETP or Mass transfer coefficient data is generated in-house on test rigs or cited through literature for similar configuration.

High pressure gas-liquid separator: Our patent pending high pressure gas-liquid separation system help to complete material balance during chemical reactions. Complete condensation of reaction products avoids flashing during discharge. It is equipped with precision control valves; capable of withdrawing liquid upto 1ml.

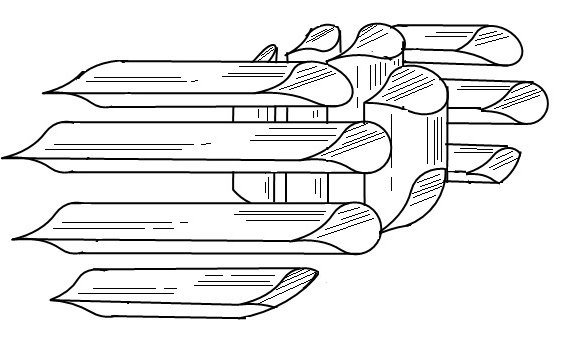

Heat Exchanger tube inserts: Tube side Heat transfer coefficients are limited by boundary layer formation and fouling due solids and salts deposition. Heat exchange tube inserts improve heat transfer coefficient by disturbing boundary layer formation and removes scale. It helps improving localize Reynolds number. Improved heat transfer coefficient helps in decreasing utility temperature thus helps in reducing skin temperature.